Real-World Results

![]() The University of Maine in Orono is among the nation’s most environmentally responsible institutions according to the Princeton Review, one of the nation’s top education service and evaluation companies. It recently listed the university on its Green Honor Roll with a rating of 99 (the highest score). Michael Swartz, Energy and Utility Manager at the university, is not surprised that the University is one of only 18 elite colleges and universities to receive the honor. “From the administration on down to the student body, the commitment of the university to energy and environmental sustainability issues in its practices, use of resources, and academic and research programs is very much in evidence.”

The University of Maine in Orono is among the nation’s most environmentally responsible institutions according to the Princeton Review, one of the nation’s top education service and evaluation companies. It recently listed the university on its Green Honor Roll with a rating of 99 (the highest score). Michael Swartz, Energy and Utility Manager at the university, is not surprised that the University is one of only 18 elite colleges and universities to receive the honor. “From the administration on down to the student body, the commitment of the university to energy and environmental sustainability issues in its practices, use of resources, and academic and research programs is very much in evidence.”

Opportunities for Improvement

Given the university’s commitment to environmental sustainability, the university’s energy team is continually looking for ways to conserve energy.” We look for every opportunity for improvement,” Swartz said. Recently, one of those opportunities presented itself when Auburn Manufacturing Inc. (AMI) approached the university to participate in a pilot demonstration to test a new insulation product designed to reduce the cost of wasted energy and reduce carbon emissions.” AMI offered the insulation and help with the installation. Coincidently, we had a boiler replacement project underway in our service building, so the timing was perfect. The building is a large, stand-alone, one-story structure that houses facilities management, central stock and supply, purchasing and several trade shops. The new boilers had exposed piping that required insulation. Our insulation contractor, Northeastern Insulation Service (NIS), applied the Cut ‘n Wrap to the fittings in conjunction with insulating the straight lengths of pipe.”

Designed for Quick and Easy Application

AMI developed its new Ever Green Cut ‘n Wrap insulation as an alternative to custom-made blankets for insulating bare piping components such as valves, flanges, pipe fittings and other hard-to-get-to components. Ideal for retrofits in institutional and commercial facilities where temperatures are below 500°F, Cut ‘n Wrap is quick and easy to fit, cut and fabricate on-site. It comes in a kit, which contains a 4 ft. x 8 ft. modularized insulation sheet fabricated from industrial-grade coated fabric and insulation media, as well as a roll of double sided hook and loop fastener.” You simply measure and cut the insulated material to size, wrap the exposed valve or fitting and secure with the supplied self-sealing hook and loop attachment systems,” explained Matt Lampron, Business Development Manager of AMI.”Installation takes only minutes per valve or fitting. And since they are reusable, Cut ‘n Wrap insulation covers are ideal for those valves and fittings that require periodic maintenance or inspection. Independent testing has shown that heat loss can be reduced by at least 85% and emissions by up to 1000 lbs/sq.ft/yr by using the insulation.”

Heat Losses are Direct Losses

The service building’s boiler room where the Cut ‘n Wrap insulation covers are installed measures approximately 20 ft x 25 ft and houses two boilers for the building’s forced hydronic system that circulates 180°F hot water. “Because the boiler room is unoccupied and because of the way it is vented, the boilers are not necessarily providing heat to the occupied portion of the building, and the heat losses from uninsulated pipe components were direct losses. We saw the Cut ‘n Wrap as an opportunity to protect against this kind of heat loss,” explained Swartz. Swartz was interested to see how the Cut ‘n Wrap covers would perform versus conventional insulation covers.” From personal experience, I can tell you that applying conventional blanket around these types of irregular fittings is cumbersome,” he said.” When we have installed insulation covers on fittings, we have found that they are very difficult to maintain over time. The demo project with the Cut ‘n Wrap was a great way to explore the viability of this new way of insulating the components.”

Estimated Heat Loss Savings and CO² Reductions

A total of 27 pipe components, including various type valves, flanges, an expansion device and elbows were insulated with the Ever Green Cut ‘n Wrap insulation. To estimate the annual heat loss savings and convert those savings to both dollars of energy saved and tons of CO2, AMI used the computer program 3E Plus® and ASTM C1129 for valve and flange areas. With an assumed operation of 8 months per year, the estimated value of annual heat loss savings is about $2,280, and the annual reduction of CO2 emissions is 7.3 tons. If the university had purchased the Cut ‘n Wrap materials, the estimated cost would have been $3,900. The payback is less than 2 years.

Great Labor Savings

In terms of opportunity for improvement, Swartz was very pleased with the installation.” We like that it is very easily applied and appears to be a very attractive investment,” he said. From conversations with the university’s HVAC technicians who were able to observe the installation of the Cut ‘n Wrap, Swartz said they found the product as easy as represented, if not better.” While some of the valves and fittings took time to install appropriately, it was much quicker than conventional insulation and a great labor savings,” added Swartz. Mike McGreevy, foreman for the Insulation Contractor, said,”The main benefit is how fast and easy it is to fabricate and apply.” He estimated it took approximately 15 minutes per valve.

Very Pleased with Performance

Even though personnel safety was not an issue in this particular installation as the pipes are out of human reach, Swartz said that Cut ‘n Wrap would be an excellent product to employ in areas where the water temperature is high enough to burn workers who touch the pipe components.” Personnel safety is a huge consideration and we would look to utilize it in those locations, regardless of energy savings,” he said.” We are very pleased with the installation and the performance thus far,” Swartz concluded.

Learn more about EverGreen® Cut ‘n Wrap™.

The University of Maine, founded in 1865, is the state’s premier public university, located in the town of Orono.

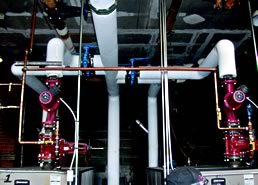

The Service Boiler Room had 27 uninsulated pipe components including several 6″ and 4″ gate valves, pumps, and butterfly valves.

Ever Green Cut ‘n Wrap blankets were installed to reduce the heat loss from the uninsulated valves and fittings on the University’s forced hydronic system.

Real-World Savings

- Project Scope: 27 uninsulated components

- Annual Heat Loss Savings: $2,280

- Annual CO² Emission Reductions: 7.3 Tons

- Estimated Payback: Less than 2 years

- Average Installation Time: 15 minutes per fitting